When size, force and precision is the challenge in your motion project

Solutions for Med tech, Life Science, Optics, Semiconductor and Advanced Industrial applications.

What challenges are you facing in your project?

Talk to us!

PiezoMotor are proud of what our customers can achieve using our products.

To inspire we share a few of our customers success stories but also some areas we have identified as areas where piezo based products should be considered.

Nanoliter precision pump

A linear motor powered by piezoelectricity from PiezoMotor ensures the required nanolitre precision for the Ginolois PMBi dispensing pump.

Experiment on electron storage ring Bessy II

In addition to flexibility and high precision, the requirements also included a design that could withstand vacuum and magnetic forces. The company used PiezoMotor actuators for this challenging task.

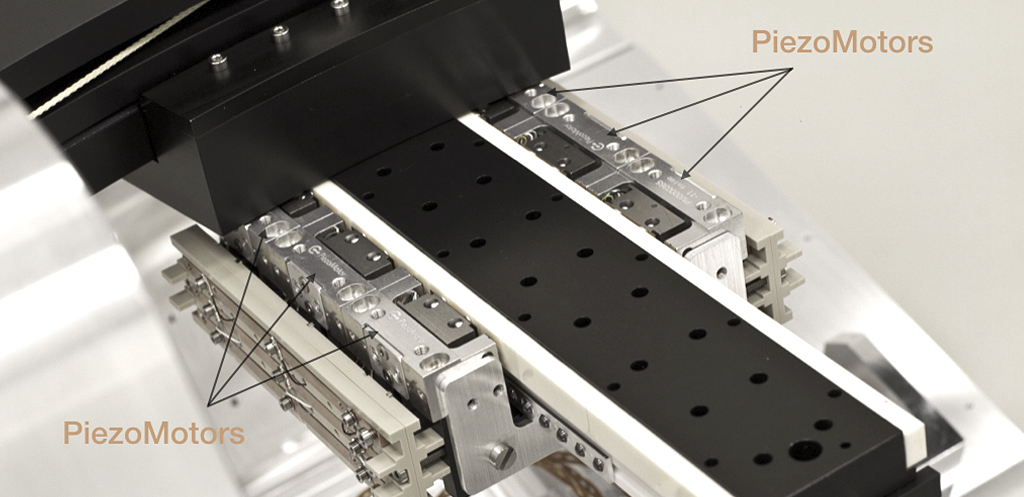

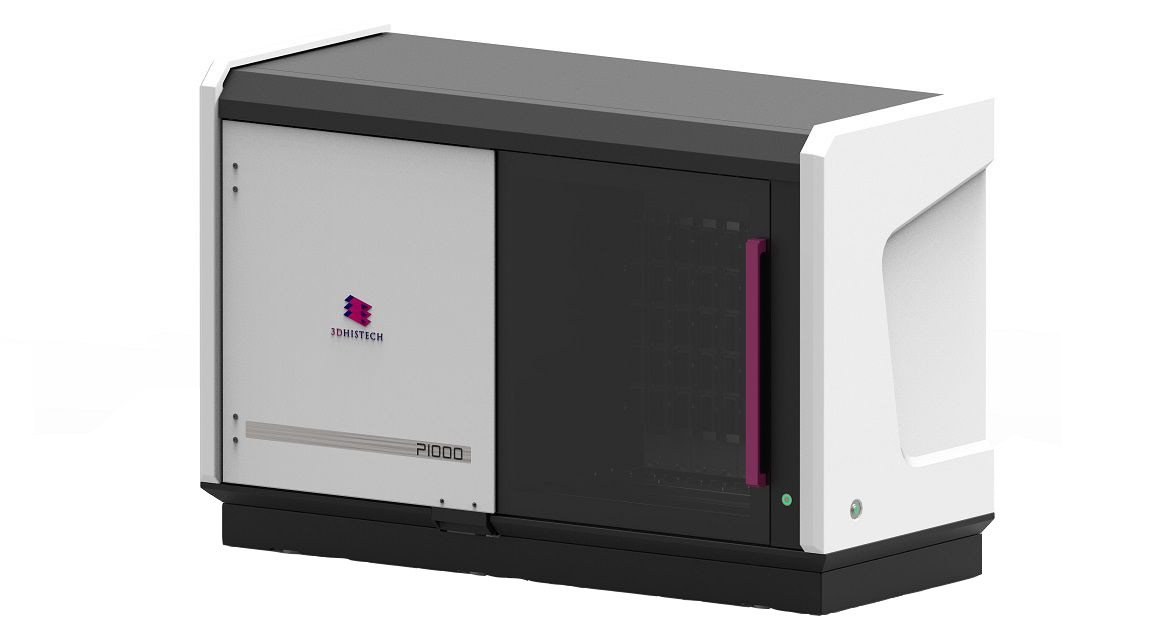

Precision and speed in lens focusing

The Z-axis, moves the objective that focuses on the samples. It must have a resolution below 200 nm. The faster the camera can focus, the more samples can be analyzed. To justify investing in a scanner, many customers demand a capacity of 300 samples per day.

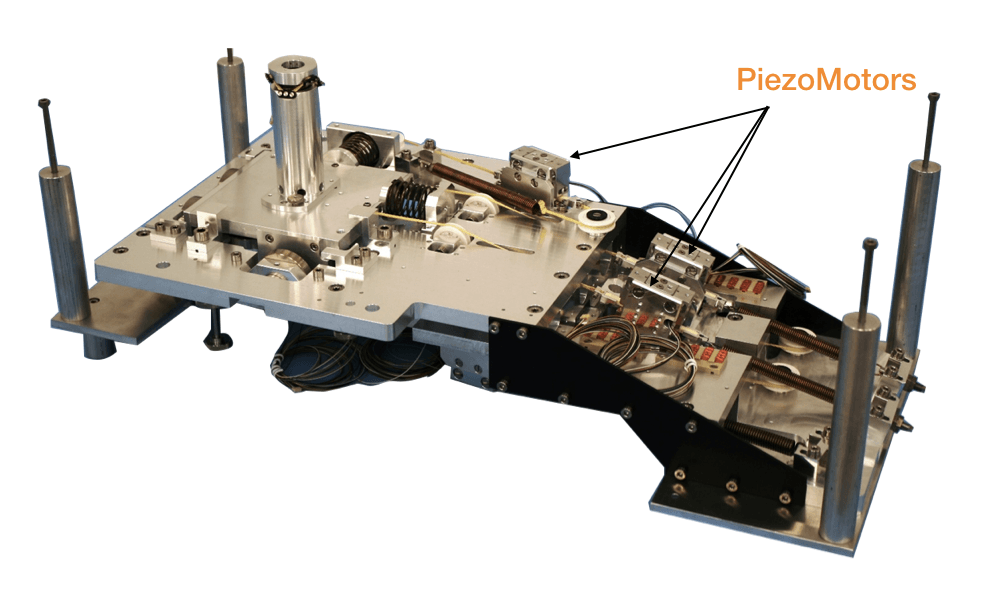

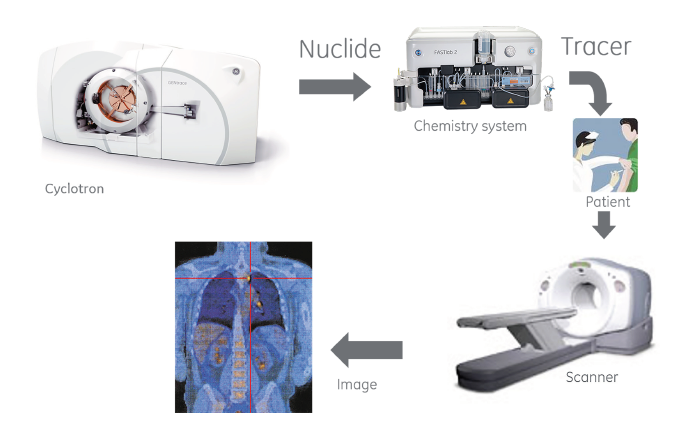

Designing a motion solution in an environment of magnetism, vacuum, and radiation

This story will tell you how PiezoMotor’s groundbreaking micro-motion solutions successfully enabled GE Healthcare to design a motorized solution inside a cyclotron with magnetism, vacuum, and radiation.

Solving the problem of the pulsating flow in a syringe pump

“The application relies on an extremely low flow rate of down to 0.1 µl/min. With a stepper motor, this means one step every minute, which creates a pulsating flow. By using PiezoMotor’s micro motor, we were able to obtain a steady continuous flow”, concludes Svahn.