GEMS PET tracer success story

How to design a motion solution in an environment of magnetism, vacuum, and radiation

With the worldwide growth of cancer treatment, the need for improved diagnostics has increased. This story will tell you how PiezoMotor’s groundbreaking micro-motion solutions successfully enabled GE Healthcare to design a motorized solution inside a cyclotron with magnetism, vacuum, and radiation.

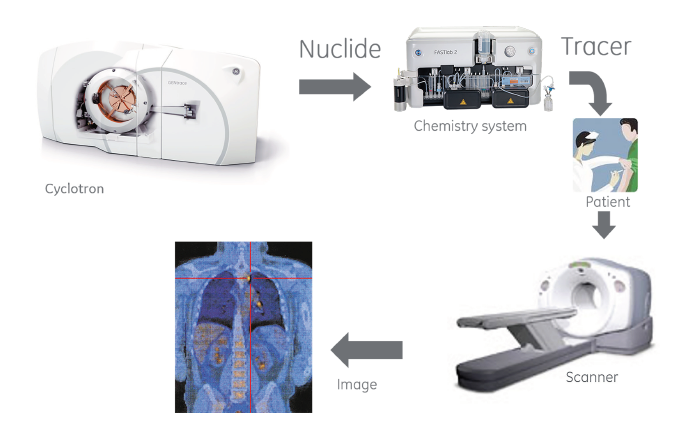

The system works in the following way:

- A specific isotope is produced in the cyclotron.

- A biologically radioactive tracer is created by radiochemistry in dedicated equipment.

- The tracer is injected into the patient.

- The tracer then attaches to specific cancer cells.

- The patient is placed in a PET scanner, and the system then detects the gamma rays emitted from the positron decay of the tracers. These light up in the regions where the tracers have attached to the target cells in the body.

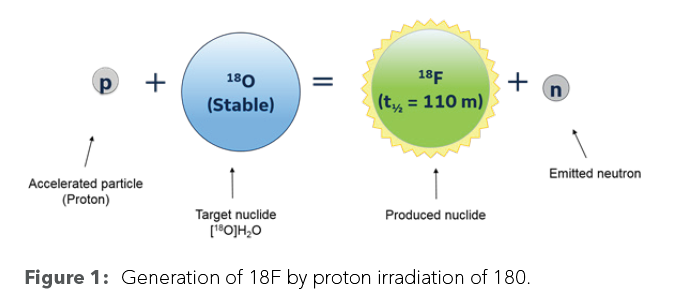

PET isotopes are produced by accelerating negatively charged ions by strong electric fields in the cyclotron and directing the resulting beam towards a reaction chamber, a so-called target, thereby irradiating its contents.

The acceleration region is kept small by strong magnetic field containment. The beam is extracted out of the magnetic containment by inverting the charge of the ions through electron stripping. Different isotopes are available through irradiation of different starting materials placed within targets designed for each reaction. For ease of use, a cyclotron is typically equipped with several targets where the beam can be moved to irradiate each of these.

High levels of ionizing radiation are created inside the target from the nuclear reaction of converting the target contents to a useful PET isotope.

Finding non-magnetic and vacuum-compatible micro-motors that could work in radiation

“Discovering the mother tumor is normally quite easy and possible through many techniques. But to discover all the metastases, where many have the size of a needle head, is often impossible. PET helps discover all these metastases, which gives the medical staff a better understanding of the spread of the cancer. This can help optimize further treatment plans and save more lives”, concludes Dr. Pärnaste.

With the worldwide growth of cancer treatment, the demand for improved and less expensive diagnostic equipment has increased. GE Healthcare Cyclotrons wanted to simplify the clinical access to PET isotopes. To solve that, the GE team had to find a solution for how to easily produce isotopes near the PET scanner, thereby overcoming the challenges of local isotope availability and half-life.

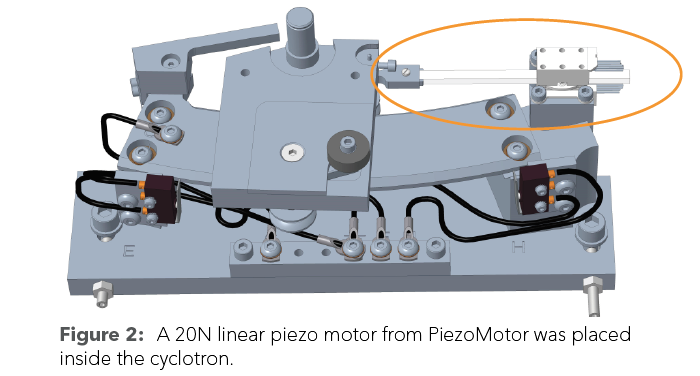

To move the beam with sufficient resolution between different targets, a motor is typically needed. However, placing a traditional electric motor inside a cyclotron in a magnetic environment, with vacuum, electric fields, and radiation, is normally not possible. The standard solution, to place the motor outside the cyclotron, inadvertently leads to a more complex mechanical construction which is more expensive and less reliable. Mechanical backlash and complicated vacuum feedthroughs are some of the consequences of such a solution.

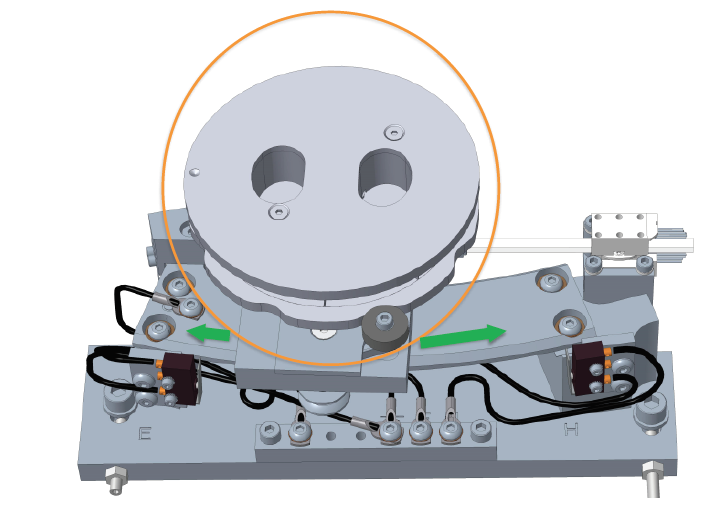

Figure 3

The piezo motor moves the extraction mechanism which in turn lets the operator make a specific isotope inside a target designed for that isotope.

By choosing a standard linear piezo motor, it was possible to place the motor close to the extraction position, inside the magnetic field and the vacuum environment, employing only electric feedthroughs to power the motor.

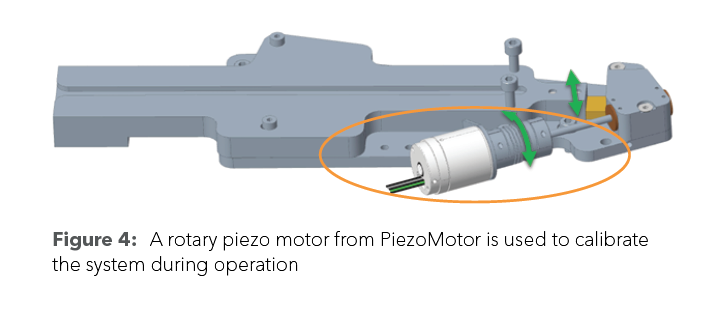

In addition to the linear piezo motor, the team also wanted to reduce the maintenance time for calibrating the system. For this purpose, they needed a completely non-magnetic motor. “The great thing with PiezoMotor as a solution supplier is their broad product range and modular design. We needed a rotating motor with non-magnetic features to calibrate the system during operation. PiezoMotor had many options for both linear and rotating motors and with different features”, Dr. Pärnaste concludes.

Dr. Pärnaste recalled that a colleague of his read an article about PiezoMotor in the Swedish tech magazine NyTeknik in 2009. All the key characteristics of the type of micro-motor that the cyclotron needed were stated in that article. When it turned out that both companies were based in Uppsala, a meeting was quickly arranged.

“After testing several micro-motors and motion solutions, we finally had a breakthrough in the design and the isotope generation in the cyclotron became possible. In the final design, we used a 20N linear motor from PiezoMotor to move the proton beam and a non-magnetic rotary motor with 50 mNm torque to calibrate the system”, concluded Dr. Pärnaste.

“PiezoMotor is the supplier we are most happy with”

The product, GENtrace, was launched in 2017 with great success. Pärnaste had just returned from Nairobi, Kenya, where they successfully completed an installation of the new system. When reflecting on the work they did with PiezoMotor, Dr. Pärnaste concluded: “We worked closely with Andreas Danell, engineer at PiezoMotor. He was always easy to contact, and he helped us a lot throughout the development process, even with parts not directly related to the micro-motion solution. PiezoMotor has a highly competent team of engineers and they contributed a lot during our product development process. Together we made this complex innovation project possible.”

Thomas Eriksson, Chief Engineer at Cyclotron Systems, concluded: “PiezoMotor is the supplier we are most happy with, and we look forward to continuing our work together.”