Custom Curved Rail Systems for OEM applications

Curved rail systems for industrial, aerospace, and medical customers.

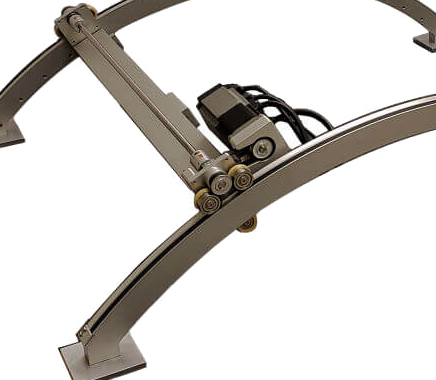

Lightweight Custom Curved Rail

with Stepper Motor Driven Carriage

For lightweight image scanning systems we design and manufacture custom curved rail arms that allow you to follow the surface contour of the object you wish to scan.

A gear tooth timing belt embedded along the surface of the rail provides the static gear rack in which a small aluminum tooth pulley powered by a stepper motor moves the carriage.

Custom Curved Rail Gantry System

with Motorized Bridge or Cross Member Structure

For transporting light payloads we design and manufacture custom curved rail systems. These are cost effective for Original Equipment Manufacturer’s (OEMs) that make a series of identical machines or instruments.

A gear tooth timing belt embedded within each curved rail provides the static gear rack in which a small aluminum tooth pulley powered by a servo motor moves the cross member.

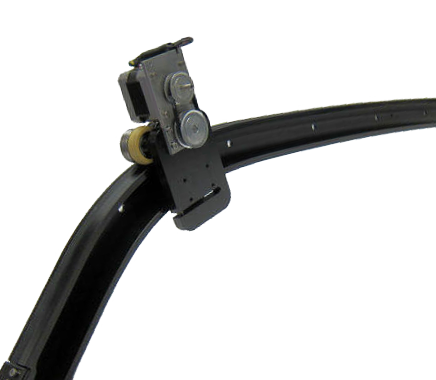

Custom Closed Loop Curved Rail System

with polymer cam roller wheels for quiet operation

For quiet operation we design and manufacture custom curved rail systems. Low profile along with tight turn radius were required for this system. Polymer cam roller wheels running on an aluminum rail surface kept vibration and noise at a low level.

Carriages move easily along the rail with very little effort.

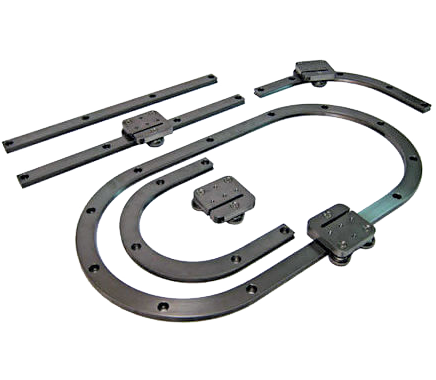

CR40 Series Products

Standard Catalog Product (Typically in Stock)

For industrial applications where you are only need a few systems or are undecided on the motion path, we offer straight, 90 turn, and 180 degree turn rail sections. One or multiple carriages can be installed on the rails. The rails can be connected end-to-end to make a complete motion path.

Carriages mate with the rails via three sealed cam roller bearings. Carriage preload is adjustable.