Acuvi LEGS® vacuum capable and non-magnetic linear actuators

High precision linear actuators with exceptional size to force ratio. Non-magnetic and vacuum capable with nanometer resolution. They provide true linear direct drive up to 40N.

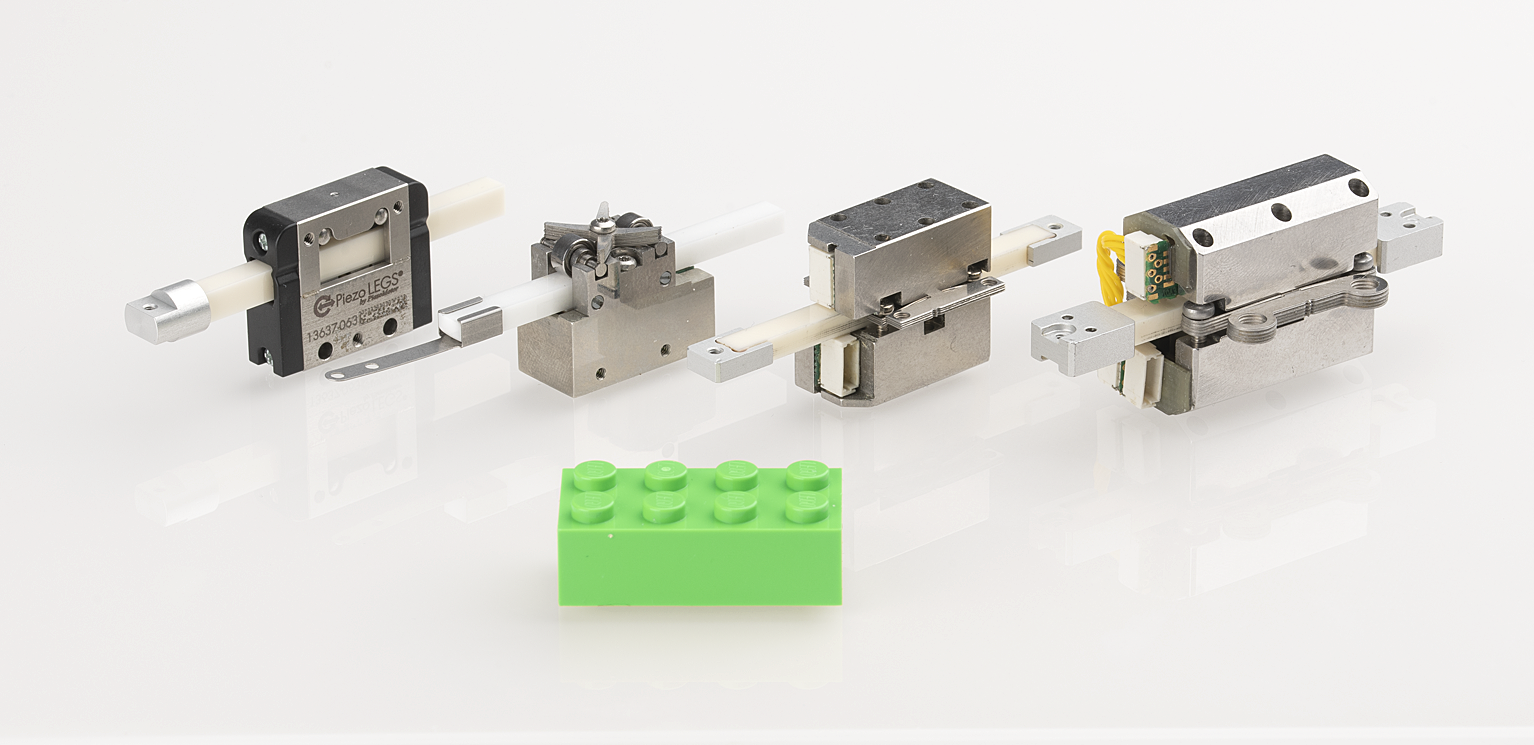

Our “off the shelf” standard 6.5 – 40N range of precision linear actuators

- Linear direct drive

- Non-magnetic

- Vacuum capable

- Extremely high resolution

- Self-locking and no backlash

LEGS® precision linear actuators / piezo motors

Patented linear actuators and piezo motors, developed and manufactured in house. We build the actuators using our proprietary LEGS® piezo technology.

Our standard range include 6.5 – 40N direct drive piezo linear actuators/ piezo motors. Our custom range include actuators up to 450N and rotary piezo motors.

Acuvi is proud of what our customers can achieve using our linear direct drive piezo actuators. They are found in Med tech, Life Science, Optics, Semiconductor and Advanced Industrial applications.

Our How to Achieve High Precision Motion Page gives insights on various motion and motor techniques.

Advantages of the Acuvi LEGS® actuators

- Vacuum capable

- Non-magnetic and do not generate magnetic fields

- Linear direct drive without the need for gears or ball screws.

- Extremely high resolution down to sub-nanometer

- Quick response and high speed dynamics

- Compact design enabling miniaturization

- Self-locking without adding power and zero backlash

- Integrated encoders available

- Precision guiding available

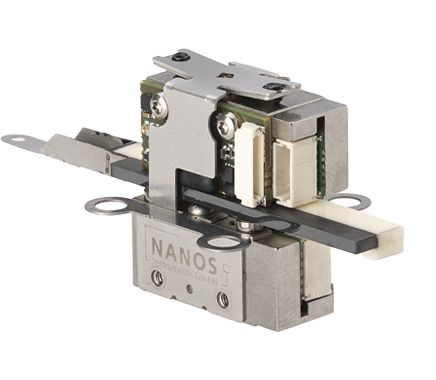

6.5N with integrated encoder

Linear actuator with guiding for standard environments

10N vacuum capable with integrated encoder

Linear actuator with precision guiding

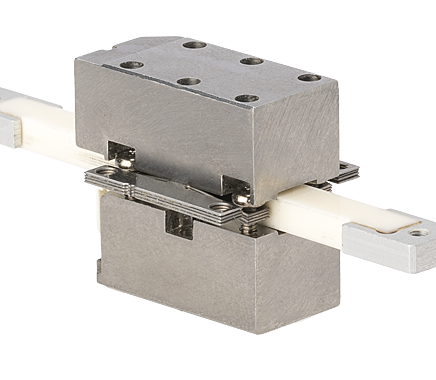

20N vacuum capable and non-magnetic

Linear actuator for external encoder

“Not finding exactly what you are looking for? Let our engineers help you with your project”

20N vacuum capable with integrated encoder

Linear actuator with precision guiding

40N vacuum capable and non-magnetic

Linear actuator for external encoder.

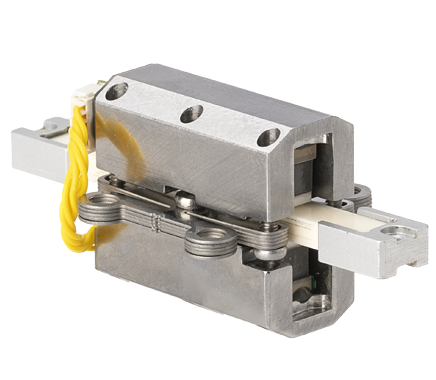

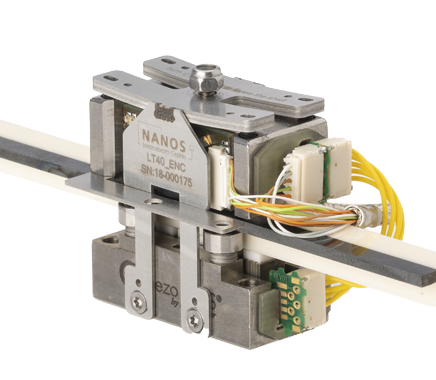

40N vacuum capable with integrated encoder

Linear actuator with precision guiding

The Acuvi LEGS® Piezo Technology is a perfect match for OEM motion solutions

Exceptional size to force ratio

Few components result in compact motors and actuators. The exceptional size to force ratio makes the LEGS® Piezo Actuator Technology a great fit for OEM engineering challenges.

True linear motion simplifies engineering

No need for gears, spindles or mechanical transmissions. Achieve linear motion without complicated engineering.

Vacuum capable and non-magnetic

The option of motor housings in non-magnetic alloys and ceramic drive units results in actuatprs with a magnetic flux density lower than 1 nT at 10mm distance. They do not generate magnetic fields or are affected by magnetic fields. No problem in an MRI machine or in cellular applications.

Extreme precision – all the way down to sub nanometer resolution

The actuators can easily position down to sub-nanometer levels if needed. The electronics is the limiting factor, not the actuator.

Response Time and High-Speed Dynamics results in rapid and precise positioning

Piezo actuators are renowned for their exceptional response times and high-speed dynamics, which make them ideal for applications requiring rapid and precise positioning. Their fast response is driven by the direct action of piezoelectric elements, which can change shape within microseconds when electrical voltage is applied. This results in minimal inertia and allows for very high acceleration and deceleration rates. These actuators can achieve nanometer-level precision in motion control and maintain stability even at high speeds, making them indispensable in fields like microscopy, semiconductor manufacturing, and optics.

Speed and step length

The speed of the actuator is depending on step length and drive frequency. The indicated maximum speed on the product pages is in normal environment and for continuous operations.

Under intermittent conditions and with specific controllers, you can greatly increase the speed. Contact us for further information. The environment and payload heavily affect the step length.

Self-locking without power, no backlash and zero drift

The friction drive locks the drive rod in place without any power draw. They achieve linear motion without gears or ball screws. The motor reacts instantly both in starting and stopping.

Precision guiding and integrated encoders

Most models are available with integrated encoder and precision guiding.

Linear Actuators Starter Kits

Starter kits are available for most of our standard Piezo actuator range. In addition to the actuator configuration of you choice the kit also, without additional cost, contains:

- Controller

- Connector board

- Power supply 48 V (with 4 regional adapters)

- USB to- RS485 converter