6.5N linear actuator, non-magnetic and vacuum capable

The LL10D linear motor is intended for OEM applications with tight space requirements and a focus on precise positioning in magnetic or vacuum environments

6.5 N force, non-magnetic and vacuum capable.

- True linear direct drive

- Vacuum compatible

- Non-Magnetic

- Resolution down to sub-nanometer

- 6.5 N force

- 0-74.5 mm stroke

- Self-locking

- No backlash

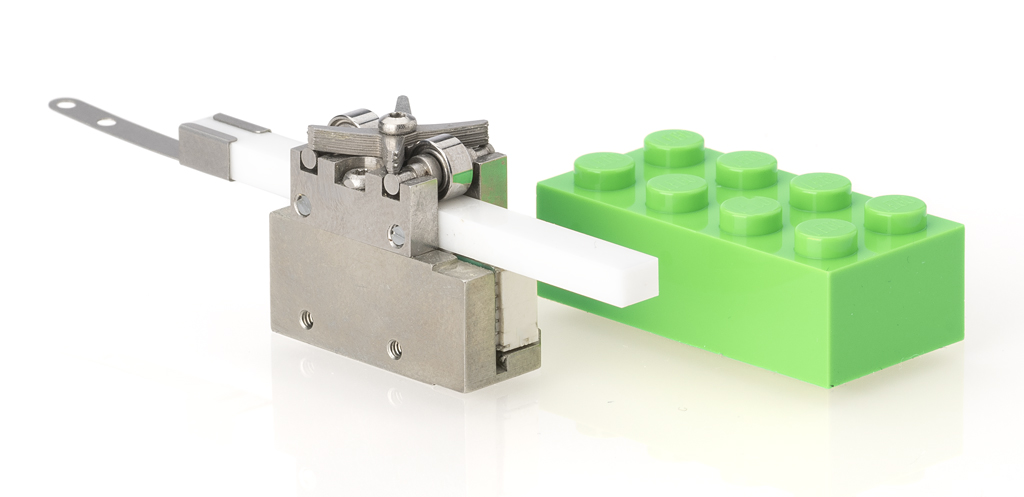

Introduction to the LL10D Piezo Motor

True direct linear drive

The LL10 linear motor is intended for a large range of OEM applications with focus on precise positioning in environments that require a completely non-magnetic and/or a vacuum-compatible motor.

The direct drive principle of the Piezo LEGS ensures motion without any mechanical play or backlash. Sub-micrometer movement is made easy with this very compact and strong motor. It replaces stepper motor assemblies when there is a need for better resolution and smooth linear movement.

Vacuum compatible

For vacuum compatibility the motor contains components, and is specially prepared, such that outgassing is minimized and that the motor can be baked at temperatures up to 125°C.

Non-magnetic

The piezoceramic actuators at the core of the motor are inherently non-magnetic and the motor housing and other parts are made from non-magnetic alloys. The magnetic flux density is less than 1 nT (sensor sensitivity in reference measurements) at a distance of 10 mm from the motor housing.

This linear actuator is also available in a 10N vacuum capable version with integrated encoder and built in precision guiding.

Specifications LEGS® LL10D

|

Type |

Non-magnetic – vacuum (D) |

Unit |

|

Maximum stroke

|

74.5

|

mm

|

|

Maximum speed

Driver dependent |

15

|

mm/s

|

|

Minimum speed

Driver dependent |

1

|

μm

|

|

Stall force

|

6.5

|

N

|

|

Holding force

|

>6.5

|

N

|

|

Vacuum

|

Yes

|

|

|

Non-magnetic

|

Yes

|

|

|

Operating voltage

|

42-49

|

V

|

|

Power consumption

|

5

|

mW/Hz

|

|

Mechanical size L x H x D

with guides and encoder |

N/A

|

mm

|

|

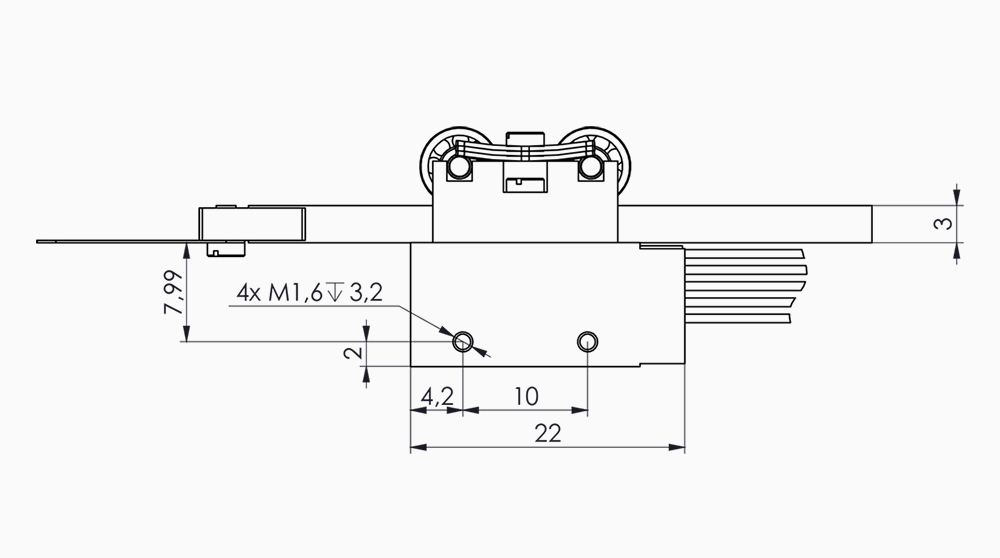

Mechanical size L x H x D

without guides and encoder |

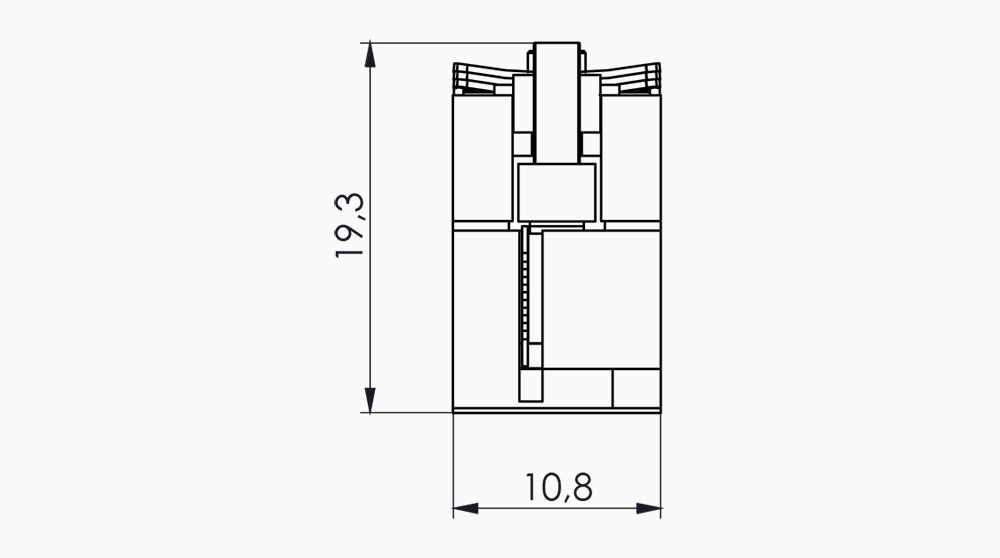

22 x 19.3 x 10.8

|

mm

|

|

Weight

with 50 mm drive rod |

23

|

gram

|

|

Material in motor housing

|

Arcap

|

|

|

Operating temperature

recommended |

-20 to +70

|

ºC

|

|

Connector motor

|

Soldered cable with JST 05SR-3S

|

|

|

Connector encoder

|

N/A

|

|

|

Resolution motor

|

<1

|

nm

|

|

Built in encoder

|

Yes

|

|

|

Encoder resolution

|

N/A

|

nm

|

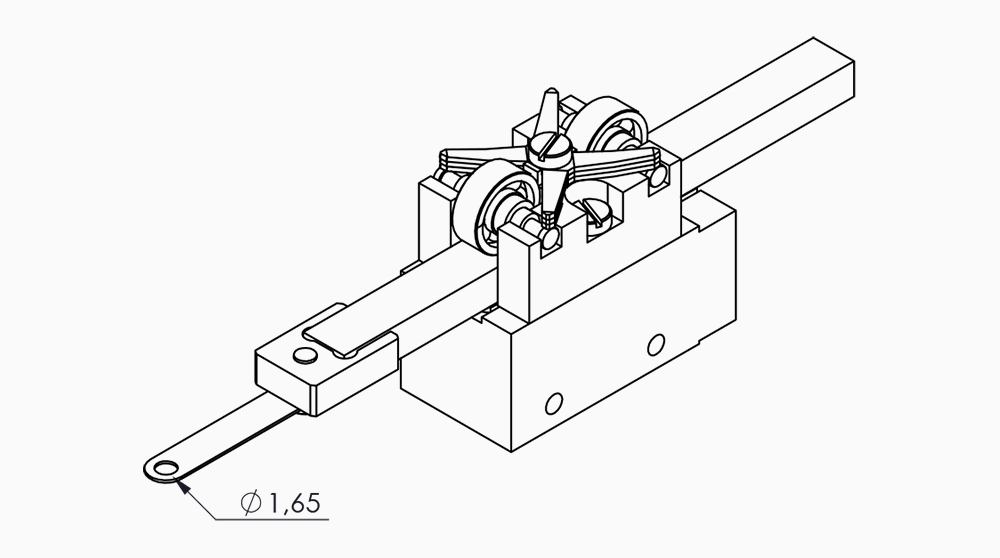

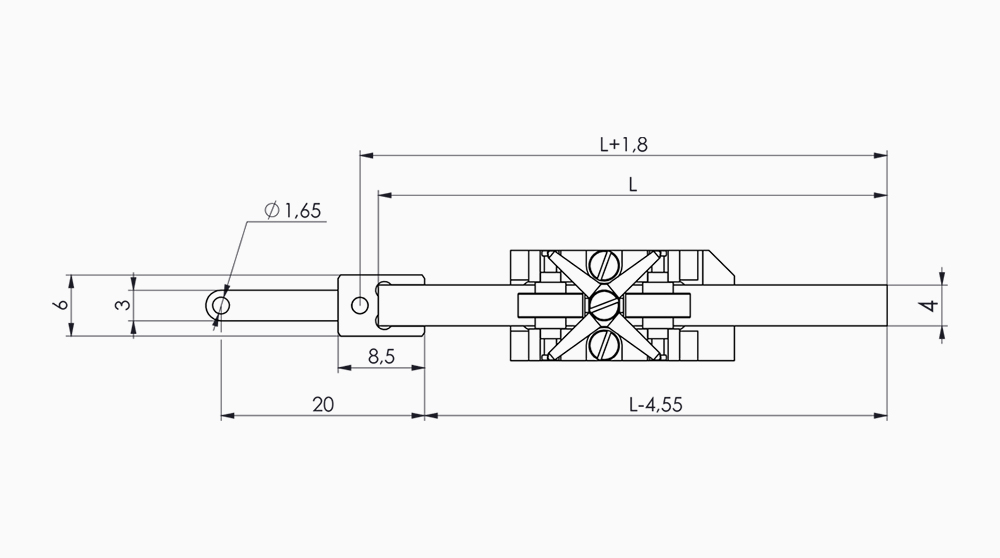

Dimensions of the LEGS® LL10D

Motor performance

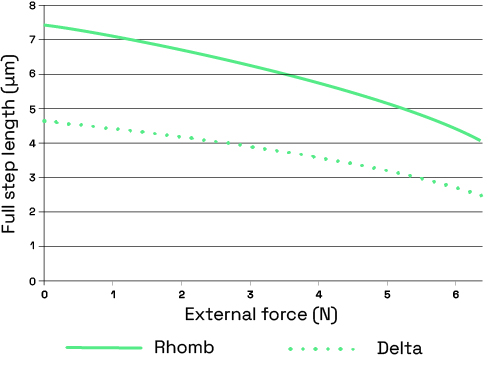

Motor performance with waveform Rhomb (filled) and waveform Delta (dotted). The full step length is the average distance the drive rod moves when the legs take one full step (i.e. for one waveform cycle).

Note: A standard deviation σ of 0.5 μm should be taken into account. Typical values are given for 20ºC.

Stroke range

|

Stroke (mm) with one adapter

|

Drive rod length (mm)

|

|

0-3.4

|

30

|

|

0-13.4 |

40

|

|

0-23.4 |

50

|

|

0-33.4 |

60

|

|

0-43.4 |

40

|

|

0-74.5 |

101

|

Motor speed at 20 ºC (missing)

|

Waveform

|

Max feq. (Hz)

|

Speed range (mm/s)

|

|

Rhomb

|

3000

|

0-15

|

|

Delta |

3000

|

0-24

|

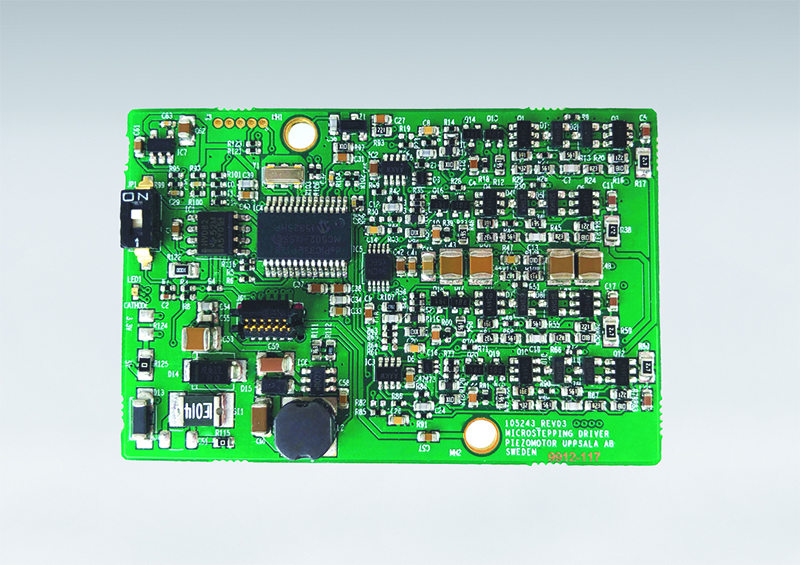

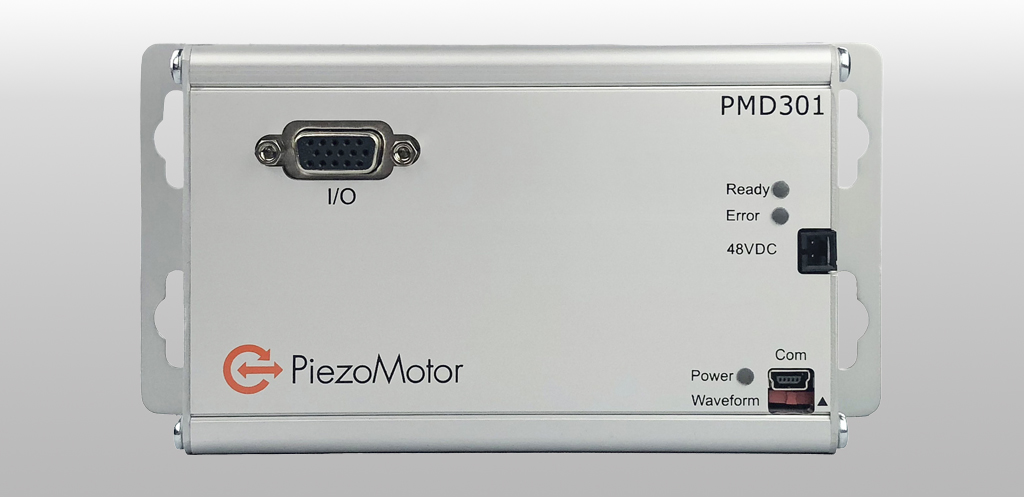

Controlling the motor

Our motor control units come in many different versions, with controllers and amplifiers for laboratory use as well as for integration into OEM devices.

We can also license the drivers for customers that want to build their own driver electronics.

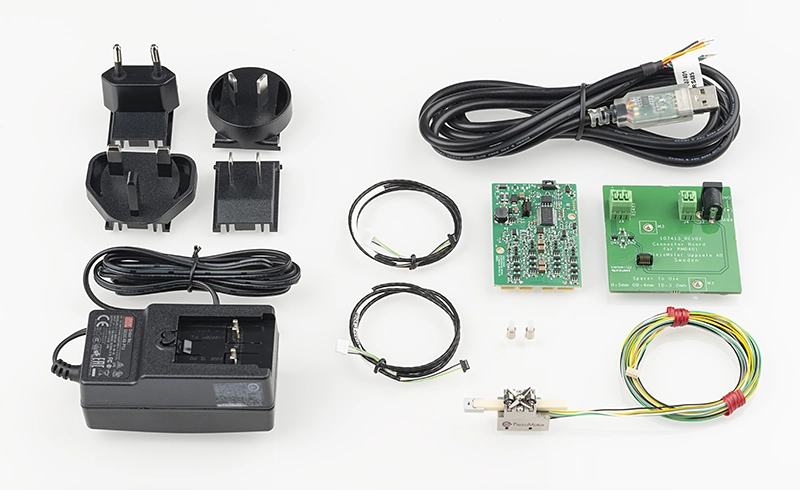

LL10D LEGS® Piezo Motor Starter Kit

Starter kits for the LL10D are available in different configurations. Starter Kits are for evaluation purposes only with a max quantity of 3 kits/customer. You only pay for the motor.