Rotary Acuvi LEGS® Piezo Motor, for vacuum and magnetic environments

A 50mNm torque output version for non-magnetic and/or vacuum environments. The non-magnetic version comes with built-in encoder or with extended shaft for customer encoder customization.

Rotary Piezo Motor with built in encoder and 50mN, torque output

- Vacuum compatible

- Non-magnetic

- Built in encoder

- 50mNm torque output

- Self-locking

- No backlash

Concept Rotary LEGS®, piezo motor for vacuum and magnetic environments

This is our rotary Piezo LEGS®, with direct drive and 50mNm torque output. The i gives closed loop resolution of 0.2 mrad (0.01°), while open loop resolution is sub-microradian. Full force power-off locking is a safety function inherent to the design.Designed for vacuum and magnetic environments.

LR23-50 mNm product portfolio

- with encoder

- without encoder

- without encoder and with extended shaft

Specifications LEGS® LR23-50

|

Type

|

Non-magnetic (C)

|

Non-magnetic (C), ext. shaft

|

Non magnetic (C), encoder

|

Non-magnetic vacuum (D)

|

Non-magnetic vacuum (D), ext shaft

|

Unit

|

| Diameter | 23 |

mm

|

||||

|

Angular range

|

360

|

°

|

||||

|

Speed Range |

0-160 (0-27 rpm)

|

°/s

|

||||

|

Step angle, full step

@ Delta, no load, 20°C |

550

|

µrad

|

||||

|

Motor resolution

14 bits, 8192 microsteps |

<1

|

µrad

|

||||

|

Built in encoder

|

No

|

No

|

Yes

|

No

|

No

|

|

|

Encoder type

|

N/A

|

N/A

|

Optical quadature

|

N/A

|

N/A

|

|

|

Encoder resolution

|

N/A

|

N/A

|

0.4

|

N/A

|

N/A

|

mrad

|

|

Stall torque

|

|

|

50

|

|

|

mNm

|

|

Holding torque

|

|

|

>50

|

|

|

mNm

|

|

Recommended operating range

|

|

|

0-25

|

|

|

mNm

|

|

Vacuum

|

No

|

No

|

No

|

10-7

|

10-7

|

torr

|

|

Operating voltage

|

|

|

42-48

|

|

|

V

|

|

Power consumption

|

|

|

7

|

|

|

mW/Hz

|

|

Shaft load, max

radial, 6.5 mm from mounting face |

|

|

5

|

|

|

N

|

|

Shaft load, max

axial |

|

|

2

|

|

|

N

|

|

Shaft press fit force, max

|

|

|

5

|

|

|

N

|

|

Mechanical size L x H x D

|

|

|

? x ?

|

|

|

mm

|

|

Weight

|

65

|

68

|

80

|

65

|

70

|

g

|

|

Connector motor

|

JST BM05BSRSS-TB

|

JST BM05BSRSS-TB

|

Cable attached,

driver dependent |

Soldered cable w. JST

05SR-3S |

Soldered cable w. JST

05SR-3S |

|

|

Material in motor housing

|

Non-magnetic

|

|

||||

|

Operating temperature

|

-20 to +70

|

ºC

|

||||

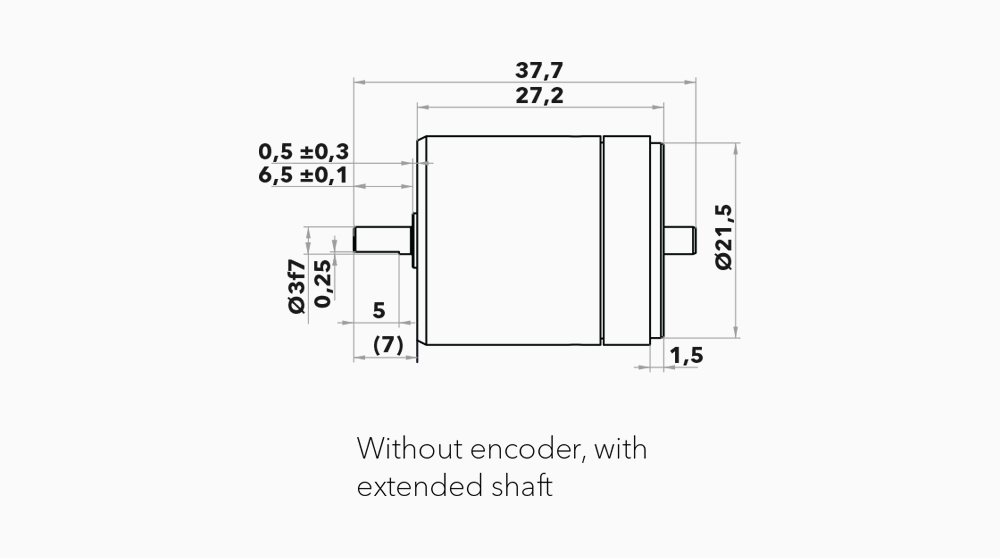

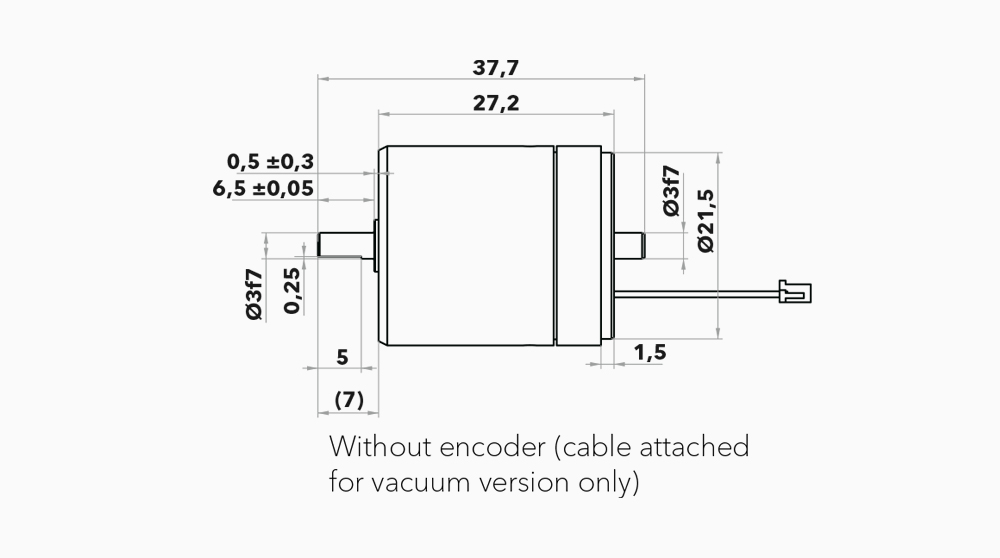

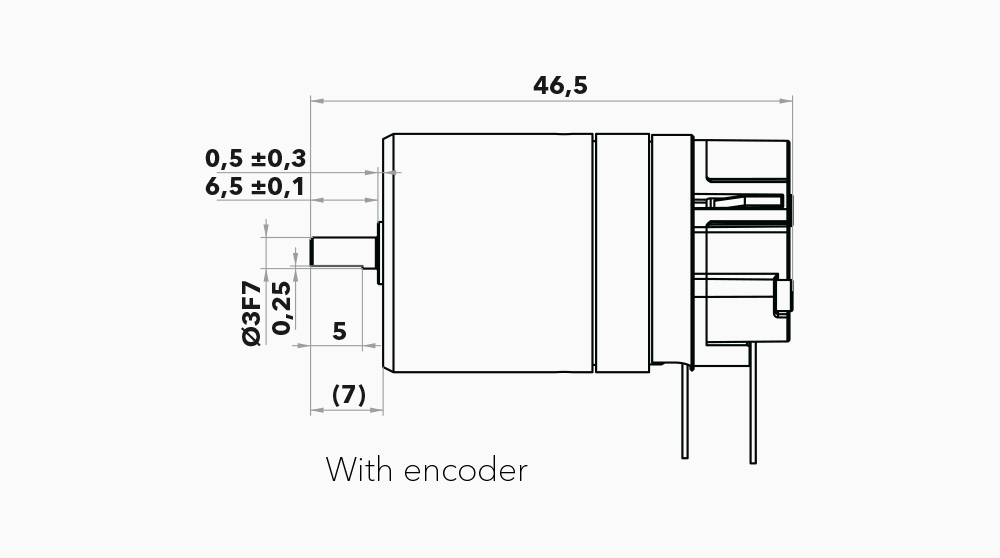

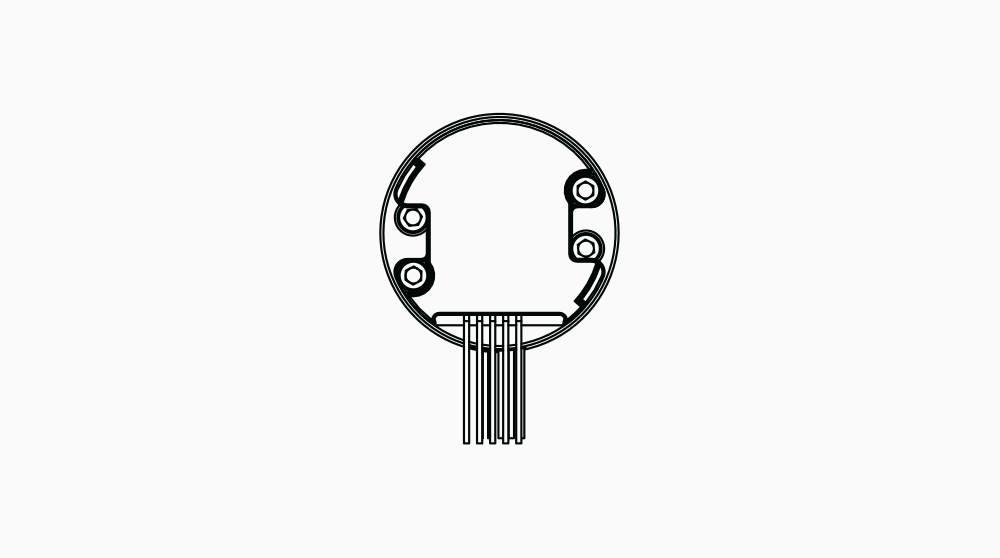

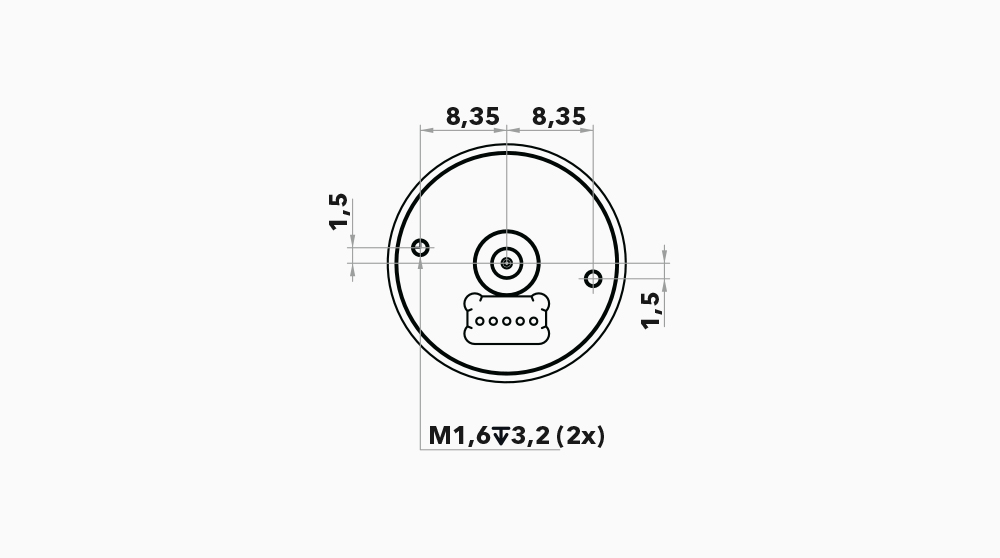

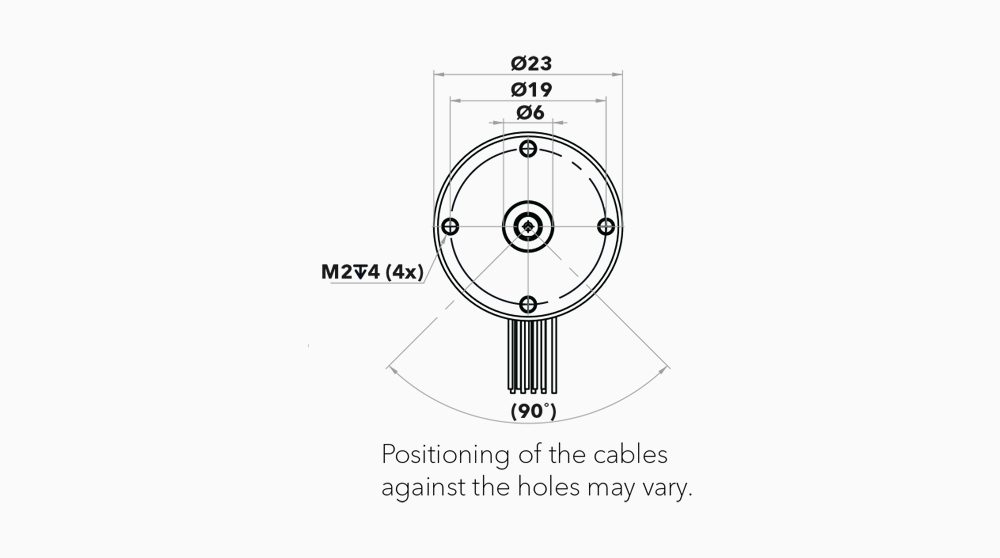

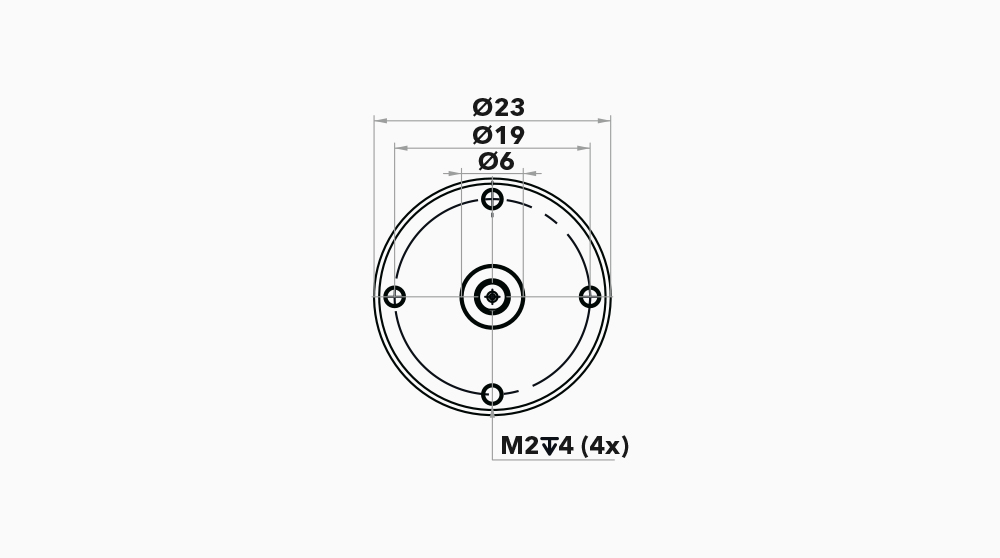

Main dimensions LR23-50

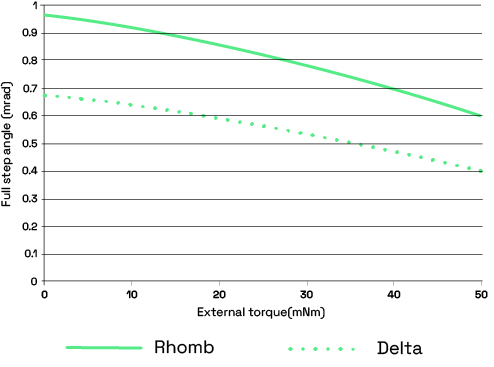

Motor performance

Motor performance with waveform Rhomb (filled) and waveform Delta (dotted). The full step length is the average distance the drive rod moves when the legs take one full step (i.e. for one waveform cycle).

Note: A standard deviation σ of 0.5 μm should be taken into account.

Typical values are given for 20ºC.

Motor speed at 20 ºC no load

|

Waveform

|

Max feq. (Hz)

|

Speed range (mm/s)

|

|

Delta

|

3000

|

0–19 rpm (0–114°/s)

|

|

Rhomb |

0–27 rpm (0–160°/s)

|

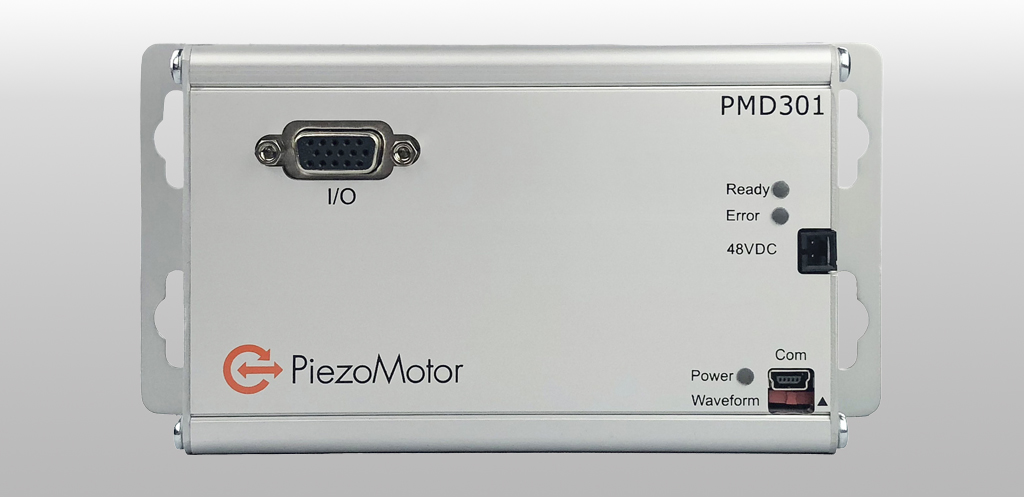

Controlling the motor

Our motor control units come in many different versions, with controllers and amplifiers for laboratory use as well as for integration into OEM devices.

We can also license the drivers for customers that want to build their own driver electronics.

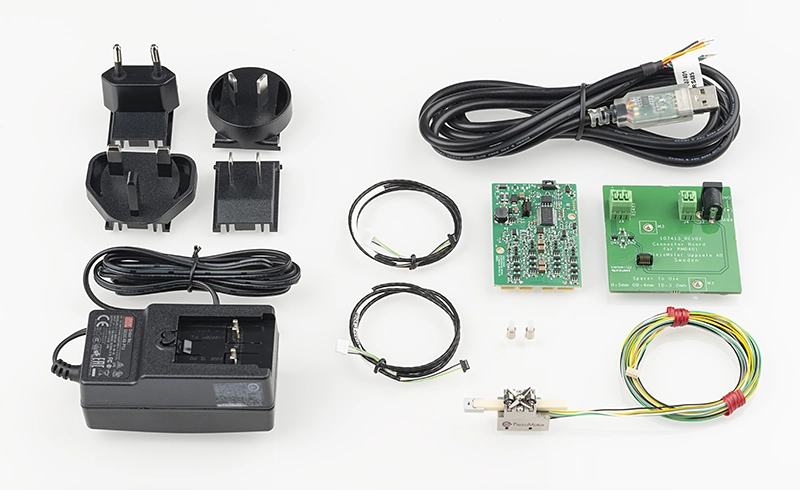

LR23-50 LEGS® Piezo Motor Starter Kit

Starter kits are available for the LTC450. Starter Kits are for evaluation purposes only with a max quantity of 3 kits/customer. You only pay for the motor.