High Temperature Linear Guides

Too hot for standard catalog products!

Have you tried our Modified Standard Products? Most off-the-shelf catalog linear guides are only rated for continuous operation up to 80 deg C (176 deg F) and intermittently up to 100 deg C (212 deg F). Sometimes all you need are a few modifications to standard linear guide block and rail products allow operation at elevated temperatures beyond their normal catalog ratings.

Do you need to extend a little or a lot above the rated operation temperature?

Products presented below will help a little, however, it you need to go really high then we will develop a custom solution for you.

SBI Series Linear Guides – Modified for High Temperature Usage

Replacing polymer components and applying a special surface treatments to standard products will push the temperature limits higher for many products.

High Temperature Assembly

(via modified standard rail and block)

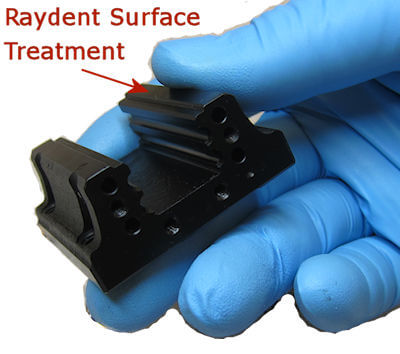

Standard SBI Series products are modified for high temperature environments. Polymer end caps are replace with all Aluminum end caps. Special surface treatments are applied such as Raydent, TDC, or TDNC.

Rail Lengths up to *2.5 meter

Suitable for temperatures up to 180 °C (356 °F)

Industry standard rail and block sizes 15 to 65

*Limited by surface treatment processor capability

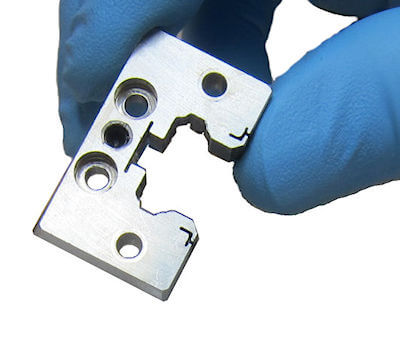

Block & Rail Special Treatment

Finished machined and heat treated bearing steel metal blocks are treated via the special process prior to moving into final assembly.

Rails are also routed through the same process since they too are typically open and exposed to the high temperature environment.

Billet Machined Aluminum End Cap

The standard polymer end caps are replaced with billet machined aluminum end caps. It’s important to remove all polymer and rubber pieces since these are the limiting factor in most block assemblies.

Caps have intricate internal routing paths to allow the balls to smoothly transition back into the block for recirculation.

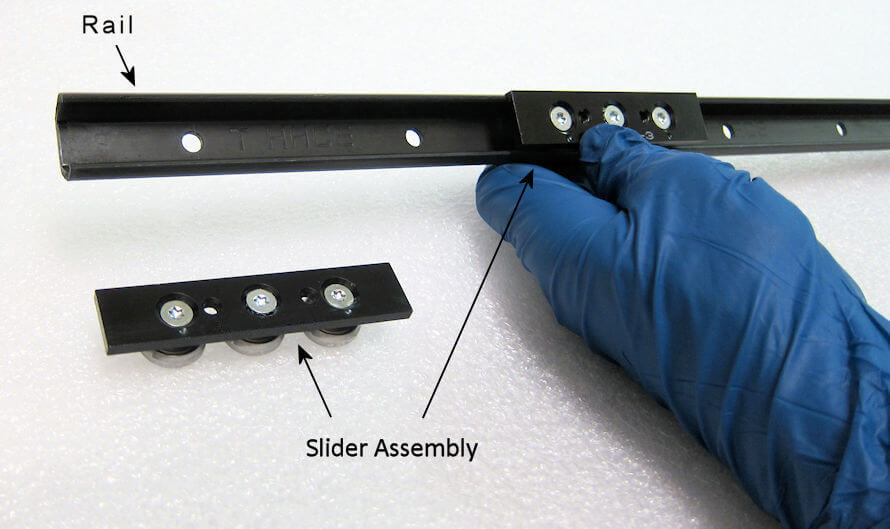

TEN rail and CEN slider assemblies – Catalog Product Can be used at elevated temperature

For light loads in applications such as door guide systems around furnaces the TEN rail with CEN slider assemblies are economical solutions up to 120 deg C or 302 deg F. This product has no polymer or rubber materials so if can operation at higher temperatures than most linear guides.

High Temperature Assembly

(via standard rail and slider assembly)

TEN is a carbon steel rail product that is hardened via the Rollon-Nox process (similar to a nitriding process with black oxidation post treatment). The CEN cam roller slider assemblies are ideally suited for various medium or light load applications in high temperature environments.

- Operate at Temperatures up to 120 °C (302 °F)

- Using TEN Rail mated with CEN cam roller slider assembly

- Rail Lengths up to 4000 mm with splicing available for longer lengths

- Available series sizes are 26 and 40

Optional Stainless steel TEX rail can be utilized in place of TEN rail if requested