Innovation meets precision

In the field of medical devices, surgical instruments and radiology devices, highly reliable, precise and safe solutions are required.

More than 20 years of innovation

Since the establishment of Piezomotor in 1998, the Acuvi brands have continuously and relentlessly pushed the boundaries of technology. Our commitment to high precision and excellence has set us apart and made a profound impact in numerous projects and developments across a wide array of application fields.

When you choose Acuvi, you’re choosing a legacy of innovation that spans more than two decades and continues to make a significant impact in the world of technology and precision.

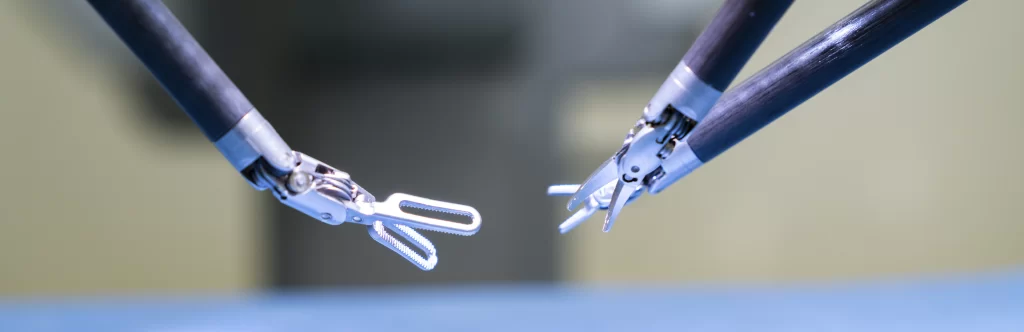

MedTech is not All about Surgical Robotics

MedTech is a multifaceted realm that extends far beyond surgical robotics. While surgical robotics are undoubtedly groundbreaking, MedTech’s reach and impact are even more extensive. It encompasses an array of life-saving innovations, diagnostic tools, patient care solutions, and advanced medical devices.

From telemedicine and wearable health tech to cutting-edge diagnostic imaging and drug delivery systems, MedTech revolutionizes healthcare on multiple fronts. It’s about enhancing patient outcomes, improving the quality of care, and advancing medical science. MedTech’s true essence lies in its capacity to transform healthcare delivery, empower patients, and drive ongoing advancements, making it a dynamic and far-reaching domain within the medical field.

Acuvi is supporting customers in multiple fields of the MedTech industry, wherever high precision and control motion is required. Our solutions are present today in Medical Devices, Imaging Systems, Clinical Laboratory and Diagnostic Equipment, Pharmaceuticals and Drug delivery, rehabilitation and assistive devices and of course in Surgical and minimally invasive Robots.

Common Challenges MedTech Engineers Face

- Precision Requirements: Any MedTech solution demands extreme precision. The margin for error is practically non-existent, whether it’s for surgical procedures or diagnostic equipment. Accuracy and repeatability are key in any motion requirement.

- Component Miniaturization: Smaller and lighter. Being for human carried devices, or for robots deployed in operation blocs, room is limited and multiplicity of technologies and devices make the environment complex. Reducing each items footprint and dead-weight is a must for patients and doctors comfort but without compromised functionality.

- Integration Complexity: Getting all the parameters right for mechatronics solutions can be complicated. One field of expertise is not sufficient enough to provide smooth motion required in medical and healthcare solutions. Surgeons must fully apprehend the robots they are working with to the point they are one with the machines.

How will Acuvi Group help You

With time and dedication, Acuvi became your go-to partner for overcoming these challenges offering the solution to match your needs in you development plan.

As an OEM supplier, we understand that each customer needs are different, and we offer specific support through the provision of components, engineering, sub-assemblies, or even ready-to-use products.

And if we do not have the right solution available right away for you, we would design, engineer, and manufacture customized precision micro motors, sub-assemblies and motion control tailored to your exact demands, within time and budget constraints.

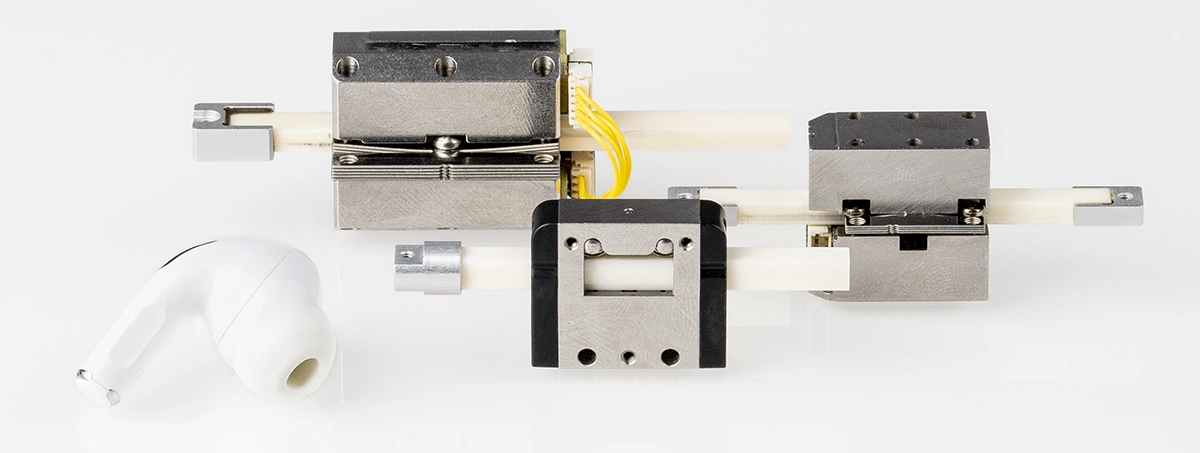

Precision linear actuators

Our linear actuators are engineered to excel in precision-critical applications. We understand that a nanometer can be the difference between success and failure in MedTech robotics. Our motors are built with the utmost precision to ensure your systems operate flawlessly.

Our PiezoMotor are using our patented technology to provide unmatched precision, down to sub-nanometer, with travel range of several centimeters in a direct drive motion. No need to worry about integration of gearbox, differential or breaks, keeping it all compact and clean from oil contamination.

And by nature, our motors are non-magnetic and radiation proof so they are compatible with live X-ray and MRI imaging during operation, without precision loss or noise generation on the image.

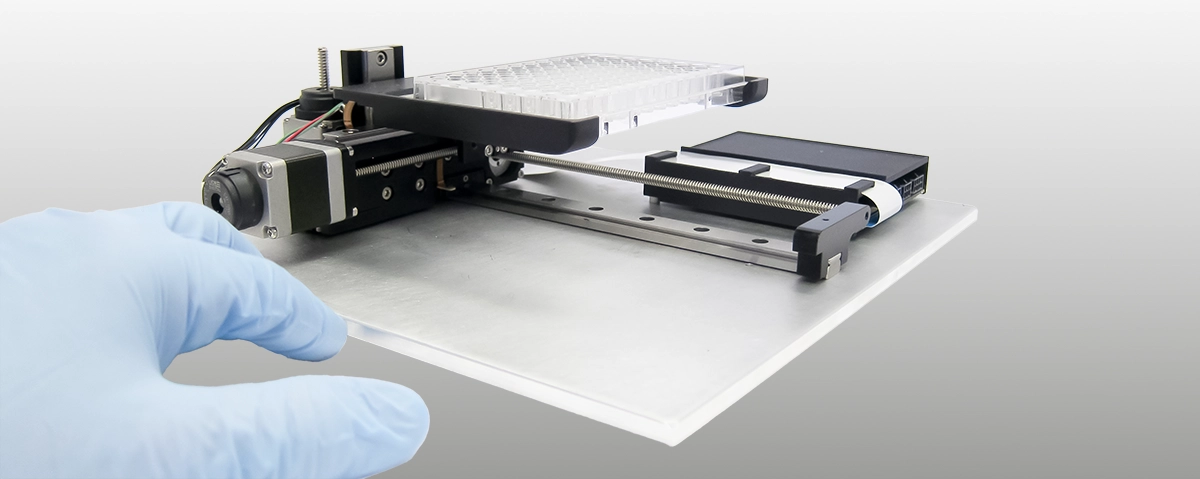

Mechanical Engineering for Sub-assemblies

We bring extensive mechanical engineering expertise to the table.

From mechanical engineering support to full system supply, our Engineering team can support in any phase of your project.

Based on our growing portfolio of customer specific bearing, slides, lead screws and other mechanical parts for difficult environments, Acuvi can support you with designing sub-assemblies that fit seamlessly into your systems to optimizing the mechanical aspects of your devices.

We’re here to enhance your designs and support you bringing your ideas as fast as possible to the market.

Drivers Platform Integration

Mechanical motion is nothing without control.

Acuvi offering for the most precise motors and components would not be complete without adapted electronic.

We offer a large variety of drivers for piezo (and other technologies) motors with multiple encoder compatibility for close loop control. From single channels basic controller to multi axis ones with advanced path planning capability and multi-feedback input, our expertise and portfolio allows us to offer optimized control of your MedTech device for the smoothest experience.