The Piezo LEGS technology motor

Piezo LEGS® work with friction drive, where force is created by the internal preload of the piezoceramic actuator legs in direct friction contact with the rotor or drive rod. When the legs start walking, they are always in mechanical contact with the drive rod.

- Voltage is applied to both left and right, causing the leg to extend to its fullest length

- Voltage is applied to the left part of the leg, causing the leg to extend to the right

- No voltage applied to the leg

- Voltage is applied to the right part of the leg, causing the leg to extend to the left

Step one

The first pair of legs maintains contact with the rod and moves right. The second pair retracts. Their tips bend left.

Step two

The second pair now extends and repositions on the rod. Their tips move right. The first pair retracts and their tips bend left.

Step three

The second pair of legs moves right. The first pair begins to extend and move up towards the rod.

Step four

All four legs are electrically activated.

The electronics

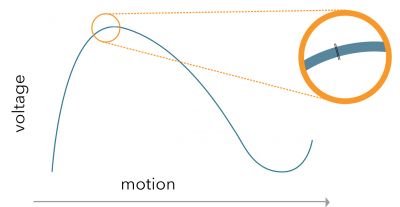

A controlled motion is created by applying voltage signals to the ceramics. The step length depends on the load as shown in the figure below. One full step can be divided into several thousands of microsteps. The length of a microstep reaches down to sub-nanometer level.

Waveform optimized for high microstep resolution

A microstep = a fraction of the waveform (full step); e.g. 8192 microsteps per waveform.