Bottom Mount Telescopic Slides

Do you have space limitations? Can’t fit traditional side mounted telescopic slides. Go with Bottom Mount!

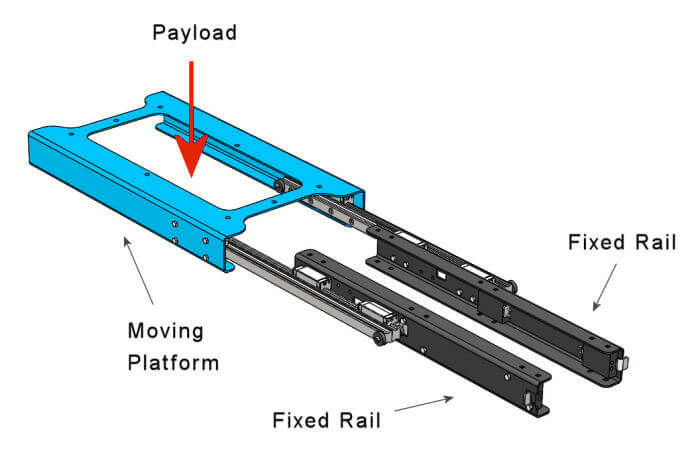

Bottom mount telescopic slides are preferred for tall and narrow openings where it is more convenient for a payload to be positioned on top of the slide assembly. Our fully telescopic units can support payloads up to 500 lbs (227 kg) with little deflection when extended.

For OEM applications where quantities of 20 pieces or more are required we can offer a bottom mount solution.

Application Details

Moving supplies into or out of contaminated environments can be challenging. In this particular case we designed a robust telescopic slide platform system that allows a person to easily move a cabinet full of supplies through a tall and narrow wall opening, presenting the cabinet inside a room allowing workers easy access to the supplies.

Very Low Profile System with Special Damper Mechanism

Platform needed to stop under load in a controlled way without jerking or shaking a supply cabinet. We developed a special dampener mechanism and life tested the assembly simulating a full load condition.

Capable of moving up to 114 kg (250 lb) payload

Structural Mounting Considerations

Installation requires the slide fixed rails to be attached to the top portion of a rigid structural member or base. The structural integrity of the base is important since it will be a factor in any deflection of the load when the slide is extended.

Approximate Physical Dimensions

|

Height:

bottom to top |

82.5mm

|

3.25inches

|

|

Width: |

571.5mm

|

22.5 inches

|

|

Closed length: |

648mm

|

25.5 inches

|

Slide Operation

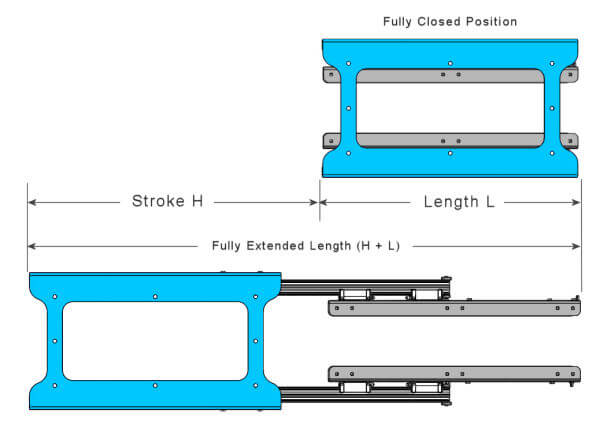

Fully telescopic slides typically stroke-out twice their closed assembly length. In this particular case we have modified the internal or intermediate element so the slide actually has more than typical extension (stroke-out) capability.

|

Assembly Closed Length (- L -)

|

648mm

|

25.5inches

|

|

Stroke or Extension (- H -) |

762mm

|

30 inches

|

Additional Feature

Standard catalog slides typically have hard stops at each end of stroke. Hard stops can easily be sheer off upon repeated hammering over time. In this particular case a sudden stop with a heavy load would cause significant oscillation or bounce in the system similar to a diving board.

To prevent sudden stops at the end of stroke we added a special dampener mechanism.