Other Piezo Motors for custom engineering needs

Our other actuator range from heavy duty linear motors special piezo motors.

They are aimed at special applications and are only manufactured after consultations with our engineers

Concept piezo actuators / motors

- LEGS® direct drive motors

- High force up to 450N

- Extremely high resolution

- Non-magnetic and vacuum capable versions

- Self-locking and zero backlash

Concept LEGS® piezo motors

Our piezoelectric linear direct drive actuators / motors are typically used in applications in the Semicon, Medtech, Life Science and Optics industries.

These concept motors are manufactured at our factory in Uppsala, Sweden after consultation with our engineers.

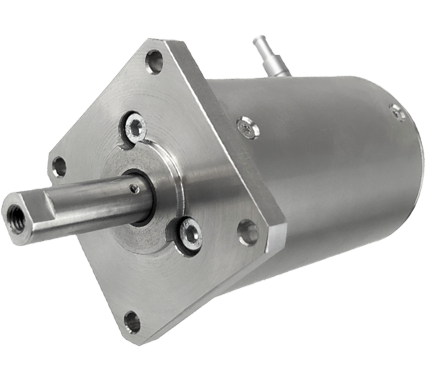

Linear 40N, covered motor

True Linear Direct drive, self locking with no backlash. Covered to shield it from dirt and dust. Normal environments

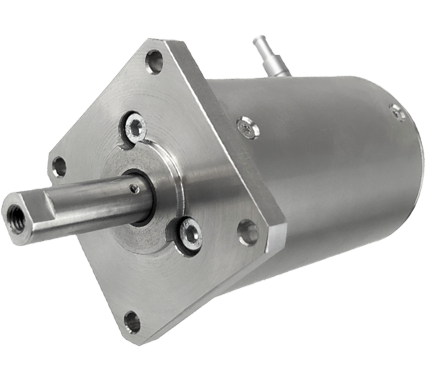

Linear 300N, vacuum capable motor

True Linear Direct drive, self locking with no backlash. Vacuum capable.

Linear 450N, vacuum capable motor

True Linear Direct drive, self locking with no backlash. Vacuum capable.

The LEGS® Piezo Motor Technology is a perfect match for precision OEM motion solutions

Miniaturized power houses

Few components result in very compact motors. Unparallelled size to force ratio makes the LEGS® Piezo Motor Technology a great fit for OEM engineering challenges.

Linear motion without gear or spindels

No need for gears, spindles or mechanical transmissions. The linear direct drive is achieved with few mechanical parts.

Vacuum capable and non-magnetic

The option of motor housings in non-magnetic alloys and ceramic drive units results in motors with a magnetic flux density lower than 1 nT at 10mm distance. They do not generate magnetic fields or are affected by magnetic fields. No problem in an MRI machine or in cellular applications.

Extreme precision

The motors can easily position down to sub-nanometer levels if needed. The electronics is the limiting factor, not the motor.

Self-locking without power draw and backlash free

The linear motion is achieved without gears or ball screws. The motor reacts instantly both in starting and stopping. The friction locks the drive rod in place without any power draw.